Well, 2018 is done and it was a year full of blessings! Most of all, Dad survived another close call and is getting better every day. He is one of the toughest old guys I have ever met. Surviving a broken Femur at 87 years old is not easy. He is doing most things for himself and tomorrow we will leave him at home for the first time since he fell. My brother is going to come by and make sure he is OK and have lunch with him.

We are going back to work tomorrow and I must say that it has been a long time since I enjoyed myself as much as I have working uninterrupted on the "Black Hole" I realized this morning that I have not had a single stress headache since I left the office the second week of December. I usually have at least two a week!!! If it doesn't do anything else for me, the car has added some stress relief into my life.

I am so thankful to God and to Traci for giving me the ability to drag race and build this awesome car. It is a great sport and I have met so many good people doing it. I am also thankful to all of you (friends and family) who follow this blog and give me support.

I have also met some really good suppliers of goods and services for the drag racing world.

I cannot say enough about how much support Mike Janis Jr. and Mike Janis Sr. have given me. They have helped me believe that I can do this and they have led me in the right direction all along the way. They have also become good friends of mine. They are truly good people!

There is also Scott at Tim McAmis Race Cars. I don't think I have ever had service equal to what Scott and Tim McAmis has given me. They always get my orders out the same day that I place them. Tim also produces a full suite of videos that have helped me to learn a lot about building a ProMod drag car. His videos are informative and funny.

Rick Jones (Quartermax) has also been very good to supply parts quickly.

Last I would like to thank Jerry and Andrea Clements for all of the prayers and support you give us to help us make it through the tough times as well as the good times.

I had a total of 53 updates to the blog this year and have posted hundreds of pictures. I hope you all have enjoyed watching my dream come true. I have really grown to love doing these updates. I never would have dreamed of taking all of the pictures and documenting this in my earlier life. I only started doing it because Clay Coleman (family friend) challenged me to document the work I do so a younger generation could learn how an old mechanic spends his spare time. Thanks Clay for challenging me.

I also use this blog to talk about how all things are possible through Jesus Christ. I am living proof of that. Look at what HE has done for me. God is Awesome!

Now, let me tell you about the last of the progress for 2018. I was hoping to start the big Hemi for the first time before 2018 ended but didn't quite make that goal. I still believe my progress has gone very well. I also still believe it is possible to test run the car some time in February.

Since the last update, I have accomplished the following:

1. All of the carbon fiber work is done except the wheel wells (called tubs). I cannot do them until I permanently mount the body. I just finished making a complicated carbon fiber piece to seal the drive shaft safety tube to the back of the chassis this morning.

2. The seat and seat belts are one. I have strapped myself in a couple of times to test the fit and make a few "VROOOM, VROOOM" sounds while i am in there.

2. All of the control cables, electrical cables, air hoses, etc. have been routed and are waiting to be terminated.

4. The crankcase ventilation system is installed and hooked up.

5. The foot controls are installed and hooked up.

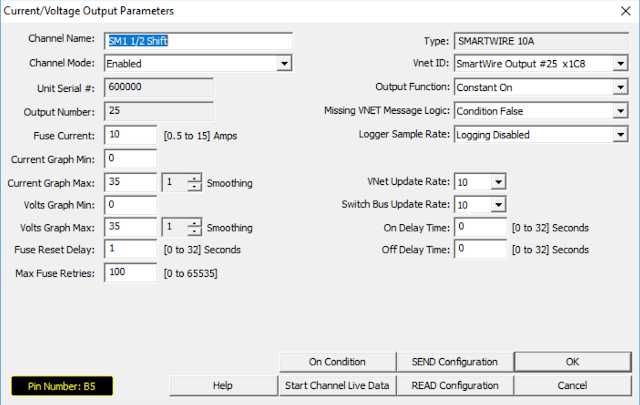

6. The shift controls are installed. These big red knobs are for manual shifting during the burnout or when manual shifting is desired.

7. The parachute handles and cables are installed.

8. The driveshaft safety loops and tube are installed.

There is probably a bunch of other stuff done that I have forgot but I will get those later.

Thanks again to everyone who supports my dream!

Click on the Blog Archive hierarchy on the right hand side to see my posts in order. The ones at the bottom are the newest posts.

Or